The working principle of BDG series electric flat car is as follows: the AC 380V power supply is stepped down to the AC 36V two-phase through the transformer and connected to the two rails respectively….

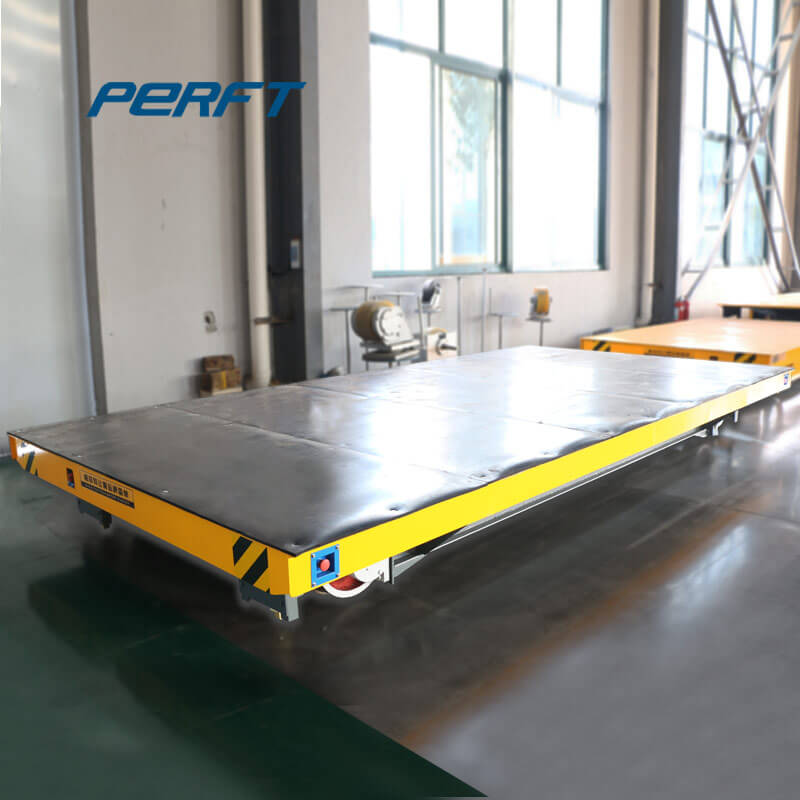

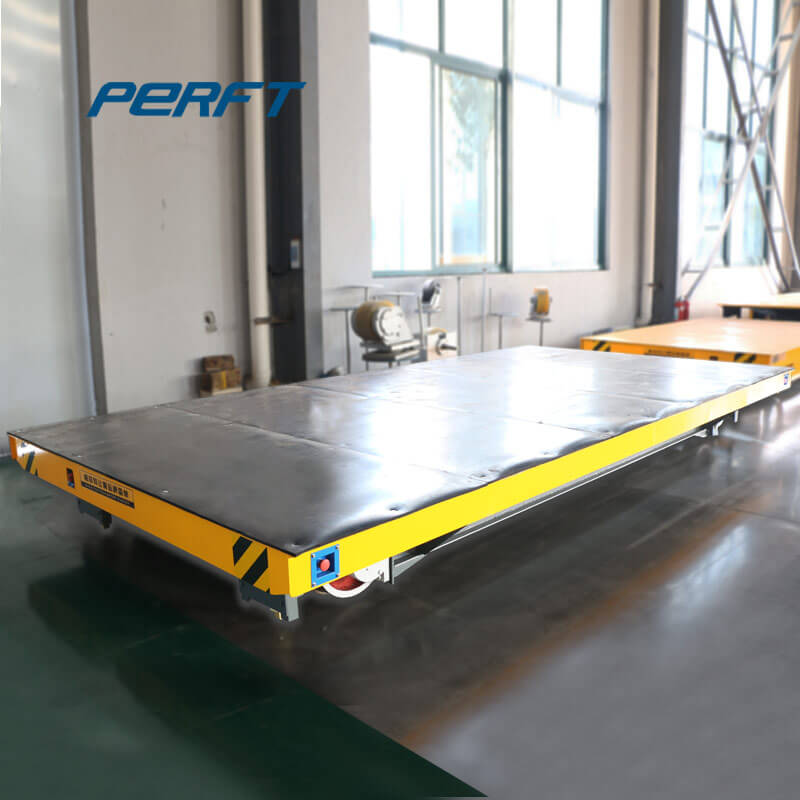

Description

The working principle of BDG series electric flat car is as follows: the AC 380V power supply is stepped down to the AC 36V two-phase through the transformer and connected to the two rails respectively. The wheels on the track flat car introduce the AC 36V power supply on the track into the vehicle electrical equipment. The box, through the rectifier module, rectifies the AC 36V to DC 36V and then controls the DC motor through the DC control system to make the flat start, stop, advance, retreat, speed regulation and so on.

Advance

This series of flat cars can be used in S-type track, curved track, and high temperature. The flat car can be equipped with the car console and pedal. It can also be equipped with hydraulic lifting system and automatic control. The flat-car DC motor has the advantages of stable starting, large starting torque, small impact on the reducer, low voltage and long service life.

Application

This series of flat cars have safety and maneuverability and has high requirements for track laying (requires insulation treatment track). It is suitable for transportation with low load capacity (≤60t), high frequency of use and medium and long-distance transportation. Not limited by distance, but the running distance is more than 70 meters, the number of transformers needs to be increased to compensate for the track pressure drop.