Jul 01, 2016 · Dung said waste water containing toxins such as cyanide and carbolic acids was released into the sea during a test run of the plant. Formosa’s $10.6bn steel complex, which includes a steel plant

Global Industrial™ Welded Steel Utility Cart, 3 Tray Shelves, 18"Wx30"L. Item #: WB800454. Not Yet Rated. $281.95. Add to Cart. Compare. Global Industrial™ Deluxe Tray Top Plastic Utility Cart, 2 Shelf, 46"Lx25"W, 5" Casters, Gray.

200 Ton Cleveland #HS2-200-54-36 Straight Side Press, Stroke 3", Strokes per Minute 50-150, Bed 36" x 54" 220 Ton Aida #NC2-220 Double Crank Gap Frame Press, Stroke 9.75", Strokes per Minute 33 SERVO FEED LINES

Feb 17, 2022 · 200 Ton Pressing, 78 Ton Pulling Brand New Dake Elec-Draulic II Double Acting Hydraulic Press, Mdl. 8-200, Electric Operation, Double Acting Cylinder, Variable Ram Speed, H-Frame Mounted Control, Self-Locking Table Hoist, Safety Valve, T-Ring Seals, Frame, 2 Forged Steel V-Blocks, Flat Ram Nose, Pressure Gauge, 2 Steel Table Plates, Pump, #SM8200

Verson and Danly Replacement Parts. Enprotech Industrial Technologies has stamping press replacement parts engineered to precisely fit your metal stamping presses. Enjoy the benefits of a secure source for replacement parts on all of your Verson and Danly presses. Since our acquisition of original Danly technology in 1997 and Verson technology

Die and Mold transfer carts loading capacity can 1 T to 200 Tons on-rails type. steerable type can be 150 Tons. battery powered, cable reel powered, 36 V rail conductor powered.

Servo Stamping Presses. Gap Frame 39 Ton – 220 Ton; Straight Side Presses 220 Ton to 4800 m. Ton

20,000 lb. (10 ton) Steel Top Adjustable Spring Loaded Compression Caster Industrial Work Horse (194832) 20,000 lbs. Capacity (40,000 lbs. pair) Download Printable PDF FEATURES Spring swivel casters for empty horse mobility with wheel lock Adjustable steel top work horses 36-60"H x 60"W

Auto Guided Carts (AGCs) End-of- Line Automation – Integrated Material Handling Systems. Motion Controls Robotics Incorporated (MCRI) will define and deliver an integrated material handling system for your manufacturing and/or warehousing operation – either as a part of, or separate from our robotic solutions – using proven, reliable and cost-effective SmartCart Auto Guided

Calculate BTU/hr. BTU/hr. = Gallons per hr x 8.33 x ?T°F. Calculate tons of cooling capacity. Tons = BTU/hr. ÷ 12,000. Oversize the chiller by 20%. Ideal Size in Tons = Tons x 1.2. If you follow these steps, you should have the ideal chiller size for your needs.

Used-200 CU.FT. Sanitary Stainless Steel Marion Paddle Blender. Model SPY-144. Mixing Chamber is 144" L x 55-1/2" W x 80" Deep. Driven by 75 HP Motor, 1770 RPM, 460 Volts, 3 Phase, into gear box. Overall Dims. Approx. 186" L x 68" W x 107" H. Mounted on Stainless Legs. Last used in Sanitary Food Plant.

2 days ago · Multi-station dies include both progressive dies and transfer dies, where notching, punching, and cutting operations occur in sequence from the same die-set. Steel rule dies , also referred to as knife dies, are were initially used with softer materials such leather, paper, or cardboard, but have also found application in cutting and shaping of

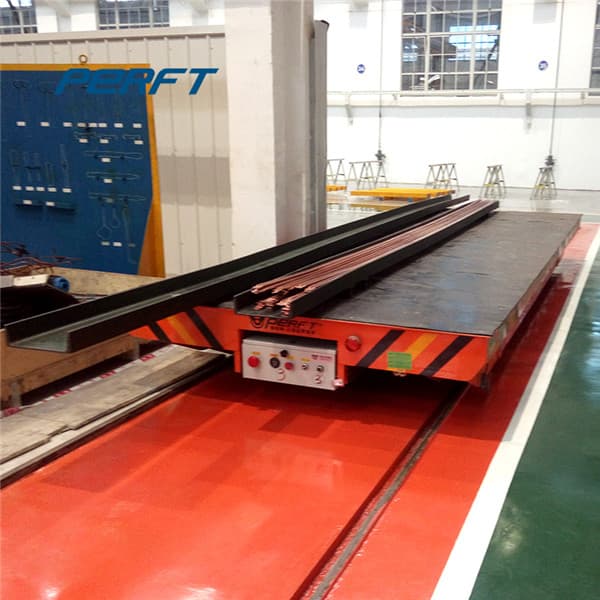

Die Transfer Cart. There will be a greater danger ifPerfect-tonnage molds are transported by crane, In order to reduce the danger, the die transfer cart was born. Warranty: 2 Years Capacity: 1-1,000 tons Certificate: CE SGS ISO9001, SASO OEM: Support Vulnerable Parts: Give as gifts

The Anatomy of a Die Cut A normal metal stamping process (creates a die cut) is to drive a sharpened tool steel punch through the sheet or strip material into a die cavity, where the slug or scrap is ejected. Cutting clearances between the punch and die are closely defined and specified in the die design stage, based on the requirement of the part.

Die stamping uses operations that include flanging, piercing, blanking, coining, and shearing. Die stamping is a method for cutting and forming metal into a specified shape. There are three types of die stamping production methods: line, transfer, and progressive with progressive being the most used.