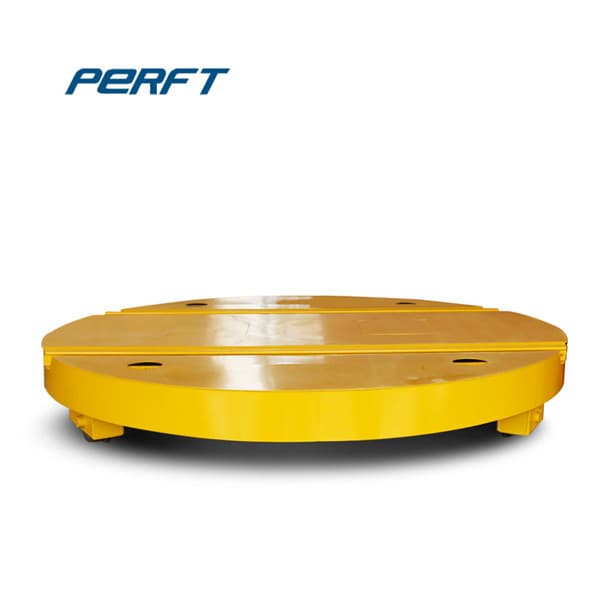

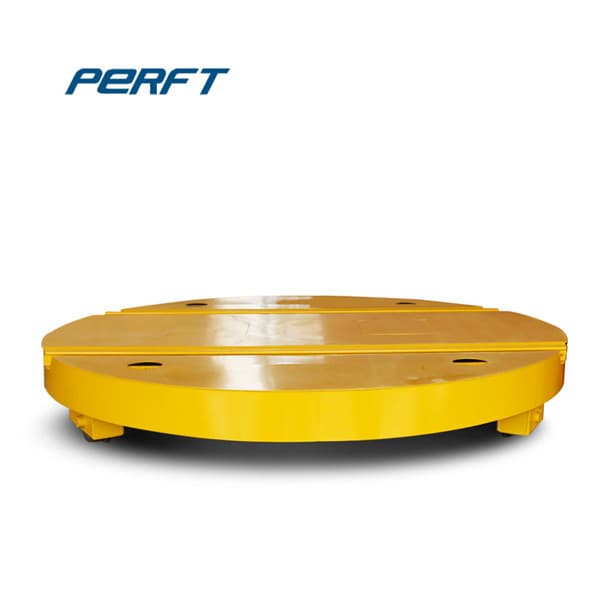

Heavy Duty Rotating Platform industrial turntable, US $ 3000 - 6500 / Set/Sets, Slewing Bearing, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Printing Shops, Construction works , Energy & Mining, PERFECT.Source from Henan Perfect Handling Equipment Co.,Perfect Transfer Cart on Alibaba.com.

Jul 14, 2021 · Perfect turntables typically use one of two technologies to provide this functionality: pneu or spring-assisted. Both types of turntable can be useful, but you’ll need to consider your facility’s workflow and floorplan to make the best possible decision.

The carts are 47" wide by 60" long and have an optional tongue and rear hitch for pulling multiple carts at a time. The carts have a 2,000 lb. capacity rating with premium poly casters and precision bearings for easy rolling when fully loaded. A heavy duty floor lock is provided.

Large Lazy Susans. An industrialPerfect lazy susan is a sturdy, ergonomic solution for movingPerfect Perfects of product. Easy to operate and set up, industrial lazy susans can be added to any workbench or table.

Working Principle. The electric material handling turntable is designed for cross rails to turn with 90 degree in warehouse and plants. Its working principle is that there are also rails installed on the turntable, when the rail transfer cart runs on the turntable, the turntable can be rotated autoally or manually until precisely connecting with the destination rail, then the transfer

High quality Propelled Rail Turntable Transfer Heavy Duty Cart Car 1-300T Load Capacity from China, China's leading Battery Transfer Cart product market, With strict quality control Battery Transfer Cart factories, Producing high quality Propelled Rail Turntable Transfer Heavy Duty Cart Car 1-300T Load Capacity products.

A wide variety of industrial rail transfer cart options are available to you, such as manufacturing plant, construction works and building material shops.You can also choose from 1 year, 2 years industrial rail transfer cart,As well as from not available, {2}, and {3}.

BZP Turntable Transfer Cart. BZP turntable transfer cart is a kind of equipment to realize the turning and reversing of the track flat car in place, and it is installed at the position where the two tracks cross. The turntable transfer car is mainly based on battery power

The heavy-duty design of these chain-driven industrial turntables is specially engineered to withstand the demands and abuses of an industrial environment, and can be controlled manually or autoally. The Series 35 family of powered. Load Capacity: Up to 6000 lbs. Maximum Dimension / Diameter: 3 ft. Power: Motor.

Rail transfer cart is an efficient material transporting cart powered by the rails, and the rails need to be insulated. We manufacture transfer carts with capacities ranging from 2 tons to over 150 tons, commonly used in machine shops, warehouses, metallurgical plants to move heavy loads throughout the facility or between crane bays.

The turntable rail transfer car is a table with the track of the turntable transfer vehicle. For the narrow space of the workshop, we have designed a model that can be rotated in place on the turntable to the designated track, and then the turntable rail transfer trolley can travel along the vertical rail.

Concrete Design and Construction Details (10.6 lbs/gal) and 10-34-0 at 85 ... the reinforcing bar will pull out of the concrete before it can transfer the entire load

Transfer Carts,Ladle Car,Coil Transfer Car,Die Transfer Cart,Railway Turntable,Transfer Cart Parts,Industrial Winch

Rail Flat Car And Turntable Transfer System--Perfte Transfer Cart. Rail flat car and turntable transfer system The project is a transfer system located in a workshop of a mechanical equipment factory in Shandong. It contains two electric turntables and a battery track flat car.

Low capacity (usually under two tons), mobile vertical lifts are manually pushed or pulled between workstations. They typically use the transfer and position (up to 12 feet high) Perfectized loads. Manually-propelled stackers can connect to batteries or building utilities and powered up and down via an operator pushbutton, foot or lever controls.